Professional Laser Engraving Toronto: The Complete 2025 Guide

Professional Laser Engraving Toronto: The Complete 2025 Guide

📑 Table of Contents

What Is Laser Engraving?

Laser engraving is a modern precision marking technology that uses a concentrated beam of light to permanently mark surfaces with text, logos, patterns, or images. Unlike traditional engraving methods that physically cut into materials using mechanical tools, laser engraving operates through a non-contact process that vaporizes the surface layer, creating clean and detailed etchings.

The process produces marks that are highly resistant to fading and wear, making them ideal for applications requiring long-lasting identification and branding. From personalized jewelry and corporate gifts to industrial component marking and architectural models, laser engraving has become the preferred choice for individuals and businesses across Toronto and beyond.

Key Characteristics of Laser Engraving

- Non-contact process: The laser doesn’t physically touch the material, eliminating risk of damage

- High precision: Can create intricate details with accuracy up to 0.01mm

- Permanent results: Engradings don’t fade or wear away with time

- Minimal waste: Laser technology produces little to no material waste

- Fast processing: Most jobs complete in minutes, allowing same-day service

- Versatility: Works on dozens of different materials and surfaces

How Does Laser Engraving Work? The Technical Process

Understanding the laser engraving process helps explain why it delivers such exceptional results. The technology relies on several key components working in harmony to create precise, permanent marks on your chosen material.

The Step-by-Step Engraving Process

- Design preparation: Your artwork or design is converted into a digital file (usually CAD format) that the laser machine can read and interpret

- Machine setup: The material is positioned in the laser engraver and the focal point is adjusted for optimal beam concentration

- Laser activation: The computer-controlled laser fires, directing a highly focused beam at the material surface

- Ablation process: The intense heat causes the material surface to vaporize almost instantly, creating the engraved pattern

- Pattern completion: The laser head moves across the material following programmed coordinates, building the complete design through precise movements

Types of Lasers Used in Toronto Engraving Services

Different laser types serve different materials and applications:

- CO₂ Lasers: Ideal for wood, acrylic, leather, glass, and non-metal materials. Most common for general engraving needs

- Fiber Lasers: Perfect for metals including stainless steel, titanium, aluminum, and anodized surfaces. Essential for industrial marking

- YAG Lasers: Specialized option for metallic surfaces and certain plastics, offering deeper penetration

Why Choose Laser Engraving in Toronto?

Toronto businesses and individuals turn to laser engraving for compelling reasons rooted in both practical advantages and superior quality outcomes. Whether you’re a corporation seeking branded merchandise or an individual wanting personalized gifts, laser engraving delivers results that traditional methods cannot match.

Superior Precision & Detail

Laser engraving’s computer-controlled accuracy allows creation of intricate designs with details as small as fine text or delicate patterns. This precision is especially valuable for professional applications like serial numbers, barcodes, QR codes, and complex logos where clarity is non-negotiable.

Permanent & Fade-Resistant Results

Unlike surface printing or chemical etching, laser-engraved marks become part of the material itself. This permanence makes laser engraving ideal for items that will be used frequently or exposed to harsh conditions, ensuring your branding or personalization withstands years of use.

Speed & Turnaround Time

Many Toronto engraving services offer same-day or 24-hour service for most projects. The speed of laser technology means you can place an order in the morning and receive completed items by afternoon, making it perfect for urgent events and tight deadlines.

Cost-Effectiveness at Scale

While setup fees exist, the per-minute laser time costs are remarkably affordable. For bulk orders like corporate gifts or promotional items, laser engraving becomes increasingly cost-effective compared to traditional methods that require expensive molds or tools.

Minimal Material Waste

The non-contact nature of laser engraving means material is only removed where needed. Unlike traditional engraving that can damage surrounding areas, laser technology creates clean marks with virtually no waste, protecting your investment in premium materials.

Versatility Across Materials

Whether you need wood, metal, leather, glass, or plastic engraved, Toronto’s equipped service providers can handle virtually any material. This versatility allows you to achieve consistent branding across diverse product lines.

Materials You Can Laser Engrave

One of laser engraving’s greatest strengths is its compatibility with a vast range of materials. Whether your project requires precious metals, natural wood, or engineered plastics, laser technology can deliver excellent results with proper equipment and settings.

Common Materials for Laser Engraving

Stainless steel, titanium, aluminum, copper, brass, gold, silver

Hardwoods, softwoods, plywood, MDF, bamboo

Transparent and colored acrylic sheets (Plexiglas)

Clear and colored glass surfaces and vessels

Natural leather for personalized items and accessories

Cotton, polyester, silk, and other textiles

ABS, PET, POM, nylon, polycarbonate (check chemical composition)

Marble, granite, slate, and other natural stone

Applications & Use Cases for Laser Engraving in Toronto

Laser engraving serves an impressive variety of personal, commercial, and industrial purposes. Toronto businesses across multiple sectors leverage this technology to enhance products, strengthen branding, and meet regulatory requirements.

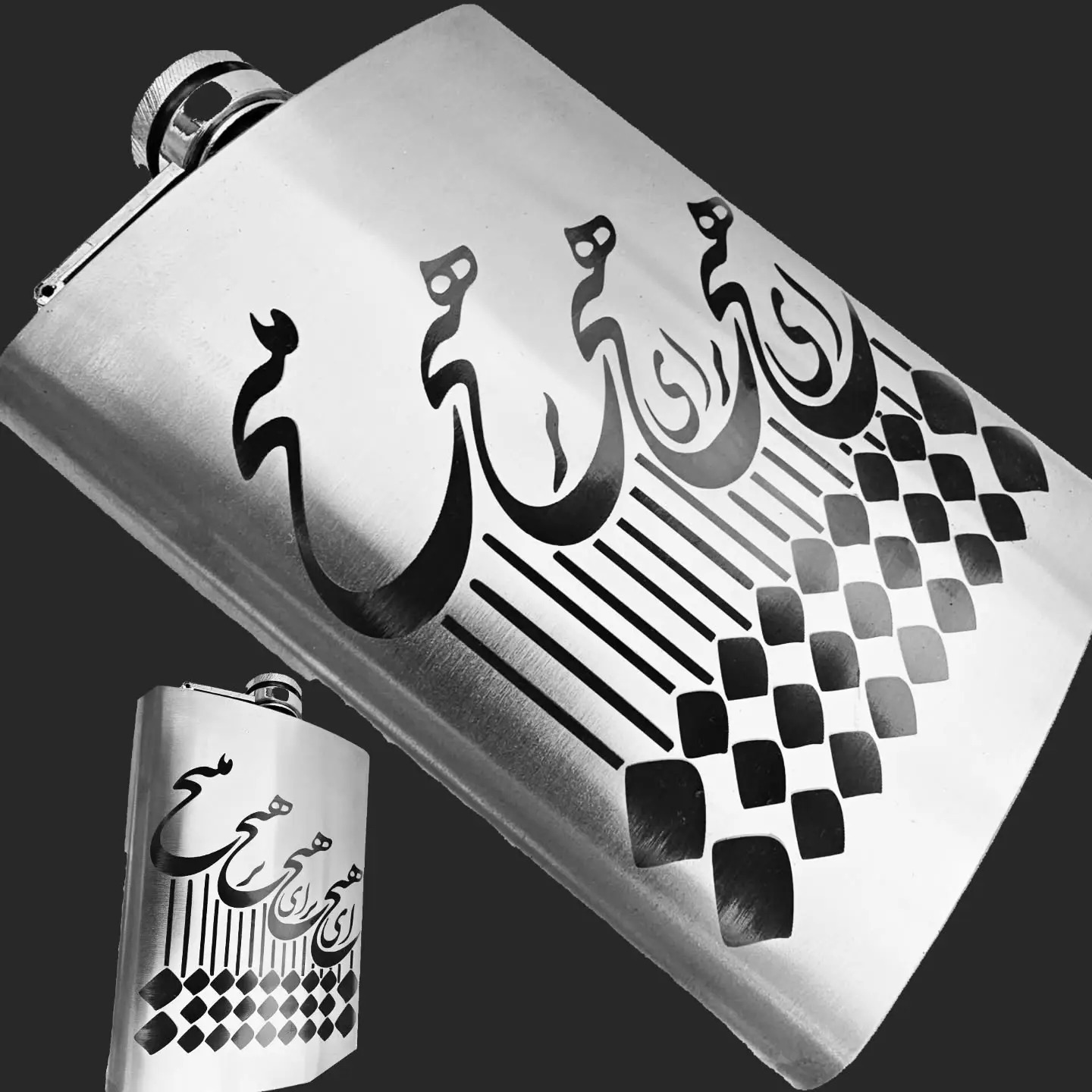

Personal & Gift Applications

- Personalized jewelry (rings, necklaces, bracelets, pendants)

- Custom photo gifts and memory items

- Monogrammed leather goods and accessories

- Engraved drinking glasses and drinkware

- Fingerprint and handwriting memorials

- Wedding favors and anniversary gifts

Business & Corporate Solutions

- Corporate gifts and employee recognition items

- Branded promotional merchandise

- Custom business cards and desk accessories

- Company logos on premium gift items

- Conference and event giveaways

- Trophy and award customization

Industrial & Functional Marking

- Serial numbers and product identification

- Barcodes and QR codes

- Control panels and equipment marking

- Tools and equipment identification

- Safety labels and compliance markings

- Prototype and part marking

Live Event Services in Toronto

Progressive engraving services now offer on-site laser engraving for events. Trade shows, product launches, corporate conferences, and brand activations across Toronto venues benefit from live personalization, where guests watch their names or messages being engraved onto premium items in 10-20 seconds. This creates memorable experiences and instant social media content while providing tangible branded keepsakes.

Cost & Pricing for Laser Engraving in Toronto

Understanding laser engraving pricing helps you budget accurately for your project. Toronto service providers use transparent pricing models based on setup time, material type, design complexity, and machine time.

Typical Pricing Structure

Most Toronto laser engraving services use this two-component pricing model:

| Pricing Component | Typical Cost | What It Covers |

|---|---|---|

| Setup Fee | $20 | Design preparation, machine calibration, focal point adjustment |

| Per-Minute Laser Time | $0.50 – $5.00 | Actual engraving time (varies by provider and complexity) |

| Character-Based Pricing | $1.50 per character | Alternative model for text-heavy projects (setup waived above 20 characters) |

Factors Affecting Your Final Cost

- Material type: Some materials require specialized lasers or longer processing time

- Design complexity: Intricate artwork takes longer than simple text or logos

- Engraving depth: Shallow marks engrave faster than deep etching

- Item size: Larger items require more laser time and movement

- Quantity: Bulk orders may receive per-unit discounts

- Rush service: Same-day or 24-hour turnaround typically costs $20-50 extra

Example Cost Calculation

Suppose you want to engrave a stainless steel pen with a 10-minute laser engraving process:

- Setup Fee: $20

- Per-Minute Charge: $1.00/minute × 10 minutes = $10

- Total Cost: $30

Turnaround Times in Toronto

- Same-day service: Available for many items (confirm availability in advance)

- 24-hour rush: Slightly faster processing with small additional fee

- 48-hour rush: Standard expedited service option

- Standard service: 3-5 business days after order confirmation

For custom quotes on your specific project, contact Toronto laser engraving providers directly. Most offer free assessments to evaluate your material, design, and requirements before providing exact pricing.

Laser Engraving vs. Traditional Engraving: A Detailed Comparison

While traditional hand engraving has centuries of history and artisan appeal, laser engraving technology offers significant advantages for modern applications. Understanding the differences helps you choose the right method for your needs.

Head-to-Head Comparison

| Feature | Laser Engraving | Traditional Engraving |

|---|---|---|

| Contact Method | Non-contact (focused light) | Direct mechanical contact |

| Precision | Extremely high (±0.01mm) | Moderate, subject to tool wear |

| Material Range | Metals, wood, glass, leather, plastic, stone | Primarily metals and soft materials |

| Speed | Fast (most jobs complete in minutes) | Slow (hours for complex designs) |

| Automation | Fully computer-controlled and automated | Requires skilled manual labor |

| Material Waste | Minimal waste | Significant material loss |

| Engraving Depth Control | Programmable precision to microns | Limited depth control |

| Fine Details | Excellent for small text and intricate patterns | Difficult for fine details |

| Hard Metal Capability | Excellent with fiber lasers | Struggles with hard metals |

| Production Consistency | Perfect consistency across batches | Varies with artisan skill |

When to Choose Laser Engraving

Laser engraving is the superior choice for:

- High-volume production runs requiring consistency

- Intricate designs with fine details and small text

- Hard metals like stainless steel and titanium

- Projects requiring quick turnaround times

- Custom and variable designs (names, dates, personalization)

- Industrial components requiring precise marking

- Non-metallic materials like acrylic, wood, and glass

When Traditional Engraving Might Be Preferred

Traditional engraving still has advantages for:

- High-end jewelry where hand artistry adds value

- Creating deep relief effects (3D appearance)

- Extremely large or irregularly-shaped items

- Heritage and artisan applications requiring human touch

Safety & Best Practices in Laser Engraving

While laser engraving is relatively safe when performed by trained professionals, understanding safety protocols ensures optimal results and protects both operators and products. Toronto service providers maintain strict safety standards and use certified equipment.

Key Safety Precautions

- Never leave laser unattended: Equipment should always be supervised during operation

- Proper eye protection: Operators wear laser-safety rated eyewear appropriate for the laser wavelength

- Ventilation systems: Fume extraction systems prevent smoke and chemical fumes from accumulating

- Fire safety: Fire extinguishers rated for electrical fires stay nearby

- Material verification: Operators confirm material composition before processing to avoid toxic gas generation

- Regular maintenance: Equipment undergoes routine cleaning and calibration

- Proper grounding: CO₂ tube machines are properly grounded to prevent electrical hazards

Safety Standards & Classification

Laser engraving equipment is classified according to international safety standards:

- ANSI Z136.1: American standard for laser safety classification

- EN60825-1: European standard for laser safety

Professional Toronto engraving services use equipment classified to meet or exceed these standards, ensuring safe operation and product protection.

Material Safety Considerations

Some materials require special handling:

- Avoid PVC and chlorine-containing materials: Release toxic fumes when laser heated

- Verify plastic composition: Different plastics behave very differently under laser heat

- Test unknown materials: Professional shops test small samples before full production

- Colored vs. transparent acrylic: Require different laser settings for optimal results

Frequently Asked Questions About Laser Engraving Toronto

How does laser engraving work?

Laser engraving uses a focused laser beam to vaporize the surface of a material, creating a permanent design or pattern. The laser is computer-controlled and directed by CAD software to create precise marks. The heat from the laser instantly vaporizes the surface material without physical contact, resulting in a clean, detailed engraving. This process works on metals, wood, glass, leather, plastic, and many other materials. The precision allows creation of intricate details that would be impossible with traditional methods.

What materials can be laser engraved in Toronto?

Laser engraving can be performed on a wide variety of materials including: metals (stainless steel, titanium, aluminum, brass, copper), wood (hardwoods, softwoods, plywood, bamboo), acrylic (transparent and colored), glass, leather, plastic, rubber, stone, fabric, paper, and cardboard. Different laser types (CO₂, fiber, YAG) are used for specific materials to ensure the best results. Avoid materials containing chlorine or PVC, as they can damage the laser equipment and release toxic fumes. Always consult with your service provider about your specific material.

How much does laser engraving cost in Toronto?

Laser engraving costs typically include a setup fee (usually $20) plus a per-minute charge that ranges from $0.50 to $5.00 per minute depending on complexity and provider. Character-based pricing is also available at around $1.50 per character. Turnaround times range from same-day to 3-5 business days. Final cost depends on material type, design complexity, engraving size, and depth. Most providers offer free quote assessments. Contact your local Toronto service for custom pricing on your specific project.

How long does laser engraving take?

The actual engraving process is remarkably fast—most small to medium items complete in just minutes. Simple text engravings might take 1-5 minutes, while complex artwork could take 15-30 minutes. However, total turnaround time includes design preparation and machine setup. For completed orders, Toronto providers offer same-day service for many projects, 24-hour rush options, or standard 3-5 business day turnaround. Live event laser engraving can personalize items in 10-20 seconds per guest.

Can you laser engrave gold, silver, and jewelry?

Yes! Laser engraving works beautifully on precious metals including gold, silver, platinum, and other jewelry metals. Fiber lasers are particularly well-suited for metal engraving. Services include inside ring engraving, personalized necklace engraving, bracelet customization, and pendant marking. Laser engraving is preferred over traditional hand engraving for jewelry because it’s non-contact (no risk of damaging delicate pieces), produces precise details, and ensures consistent results across multiple pieces. Custom fingerprint, handwriting, and symbol engravings are popular options.

Is laser engraving permanent?

Yes, laser engraving is permanent and fade-resistant. The laser vaporizes the material surface, so the engraving becomes part of the material itself rather than a surface application. This permanence means engraved items retain their markings even with regular use, exposure to weather, washing, or handling over many years. The durability is significantly superior to printed graphics, stickers, or other surface treatments, making laser engraving ideal for items meant to last.

What’s the difference between laser engraving and laser cutting?

Laser engraving vaporizes the surface layer of material to create visible marks or etchings, removing material only as deep as the design requires. Laser cutting goes completely through the material, separating pieces. Engraving is ideal for adding text, logos, images, and decorative patterns to existing items. Cutting is used to create shapes, outlines, and separate pieces from larger sheets. Many projects combine both processes—for example, cutting shapes from acrylic and engraving details onto those shapes.

Can you engrave dark items or colored materials?

Yes! Laser engraving works excellently on dark and colored materials. The laser vaporizes the surface to reveal either the material beneath (creating a lighter contrast) or creates a darkened engraving depending on material properties. Black acrylic, dark wood, dark leather, and colored metals all engrave beautifully. The contrast between the engraved area and original material creates excellent visibility. This is particularly valuable for creating high-contrast marks on colored promotional items and branded merchandise.

Can Toronto laser engravers handle bulk orders?

Absolutely! Toronto laser engraving services handle everything from one-off custom items to bulk orders of hundreds or thousands of units. This is actually where laser technology shines—once the design is programmed, multiple items can be engraved consistently and quickly. Bulk orders typically receive per-unit discounts making laser engraving increasingly cost-effective as order quantities grow. Services are ideal for corporate gifts, promotional merchandise, event giveaways, and large-scale personalization projects.

What file formats do laser engravers accept?

Most Toronto laser engravers accept common design file formats including PDF, AI (Adobe Illustrator), EPS, SVG (Scalable Vector Graphics), and sometimes raster formats like PNG or JPG. Vector files (AI, EPS, SVG) are preferred because they scale without losing quality. If you’re unsure about your file format, contact your engraving service—they can often convert files or help you prepare artwork. Many providers offer design services if you need help creating or adjusting your artwork.

Can you laser engrave photos?

Yes! Photos can be laser engraved by converting them to grayscale and adjusting contrast. The laser creates varying depths to represent different tones in the photograph, resulting in detailed photo engravings on materials like wood, acrylic, leather, and metal. This is perfect for memorial items, personalized gifts, and high-end custom products. The quality depends on the original photo resolution and the skill of the engraver in optimizing settings. Many Toronto services offer professional photo engraving with preview options before final production.

Ready to Transform Your Items with Laser Engraving?

Whether you need personalized gifts, branded corporate items, or industrial marking solutions, Toronto’s professional laser engraving services deliver precision, quality, and fast turnaround times.

Get Your Free Quote Today📞 Call us: 416-957-7544 or 647-354-4677

📧 Email: artdecoinc.ca@gmail.com

📍 Based in Toronto, serving the Greater Toronto Area